Wind Machines

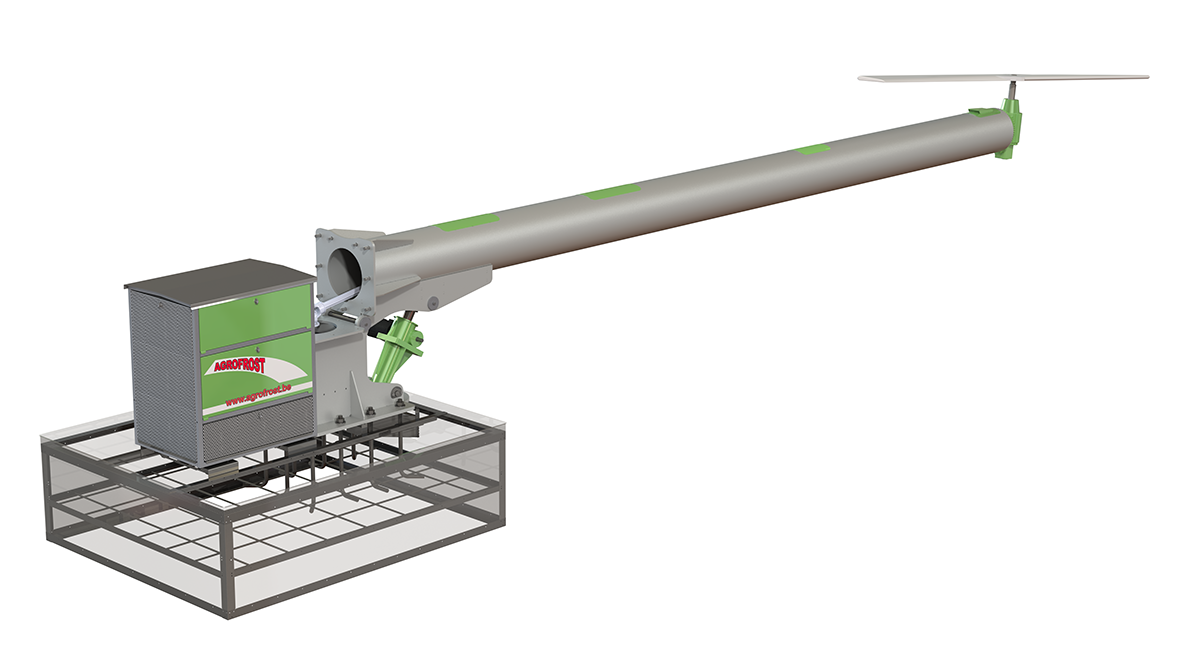

New in our program are the Wind Machines.

Our Wind Machines are available with an additional burner, that works on propane gas.

If you are looking for the most comfortable way to protect your crop, this is it! And if you want even more comfort, you can go for the Auto Start Option.

Wind machines are ideal to protect larger orchards and fields. However, a good inversion layer is essential and the protected area will between 4 and 7 hectares, depending on the kind of crop and the temperature. Protection up to – 5.5 °C.

When there is no inversion, or at very low temperatures, protection can be improved by installing an additional burner.

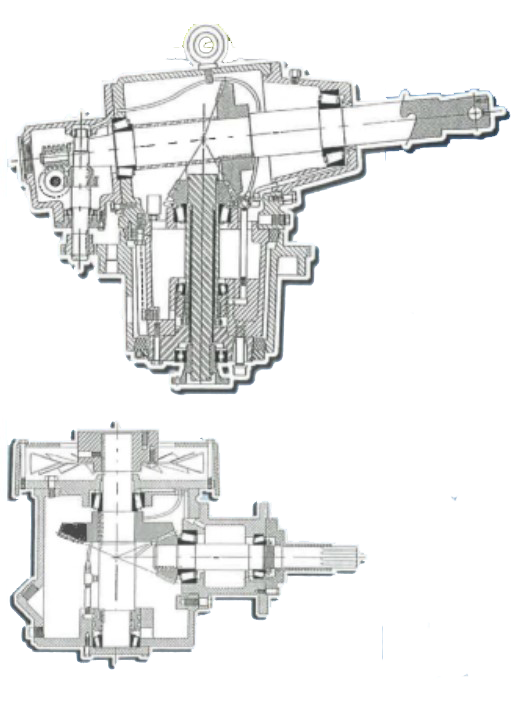

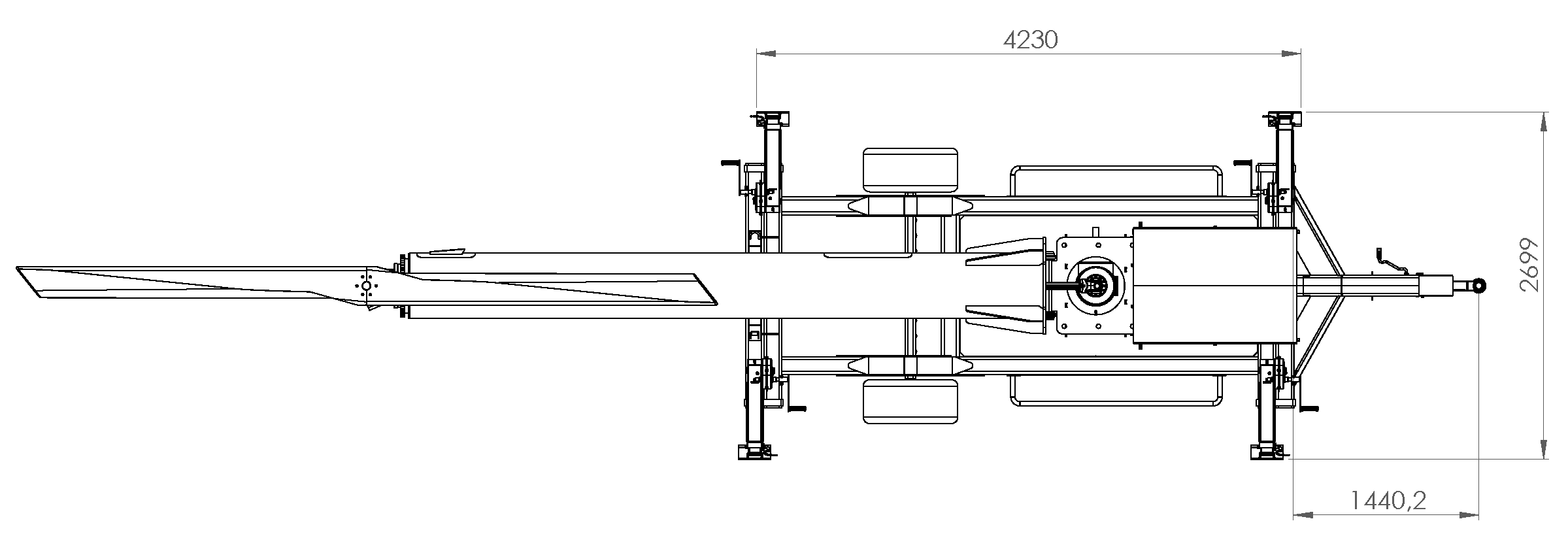

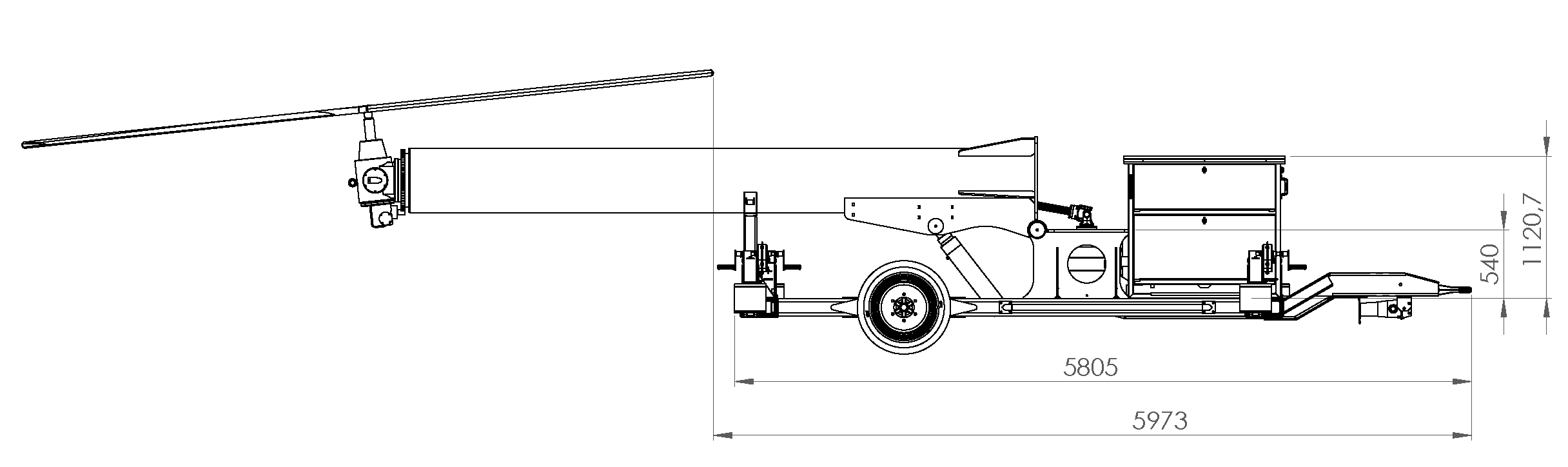

Our wind machines can also be powered with the tractor’s PTO. For this, we have a special gearbox available.

Why are we better?

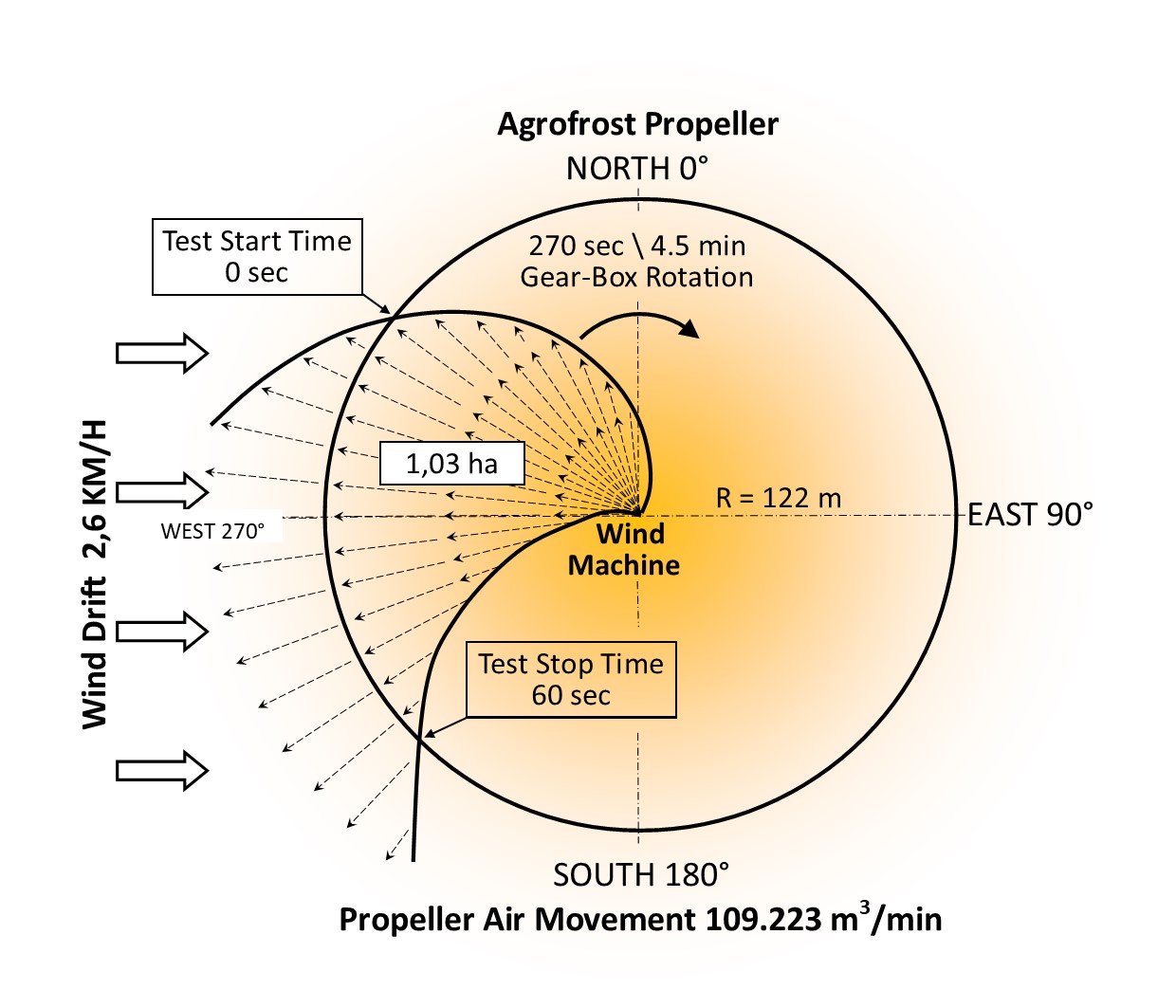

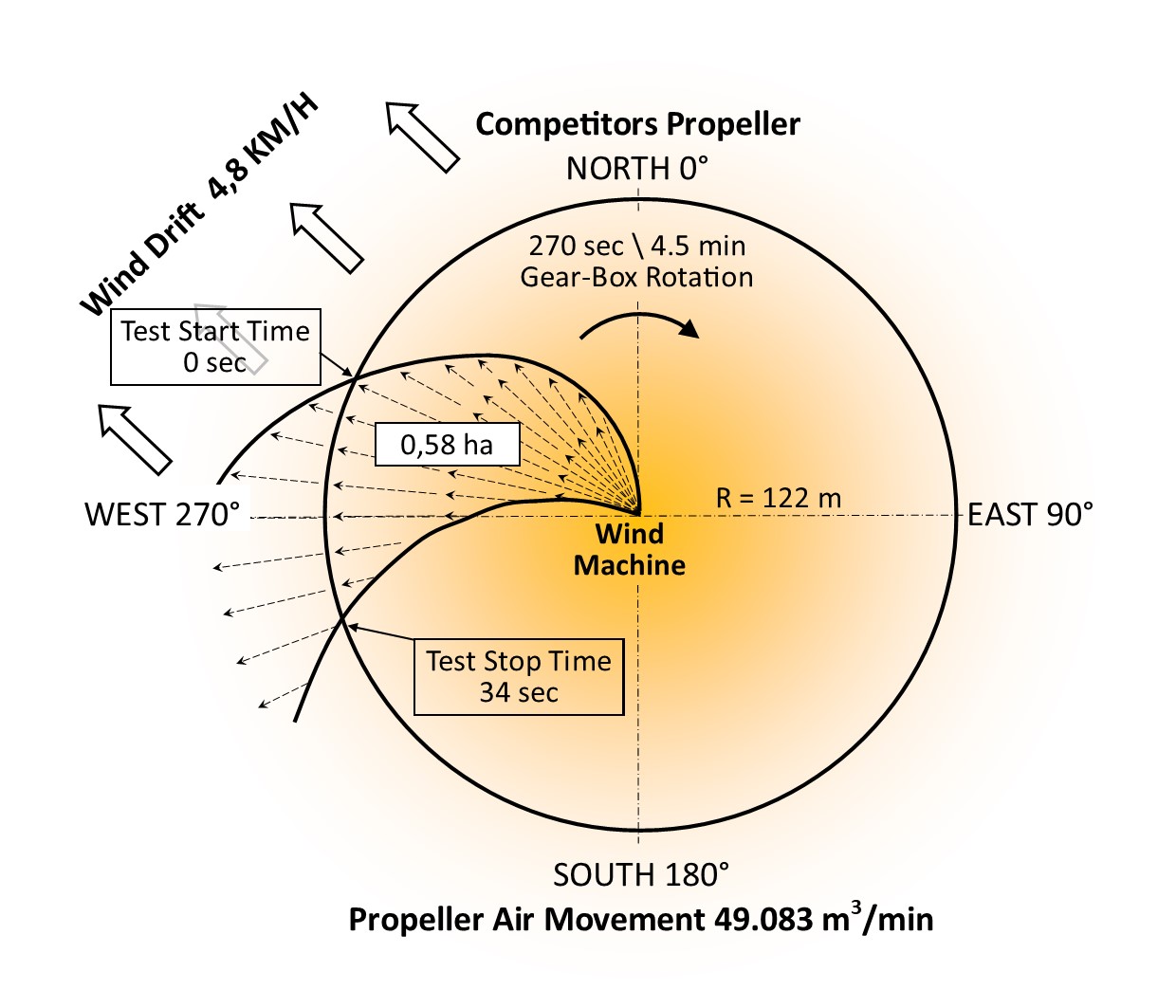

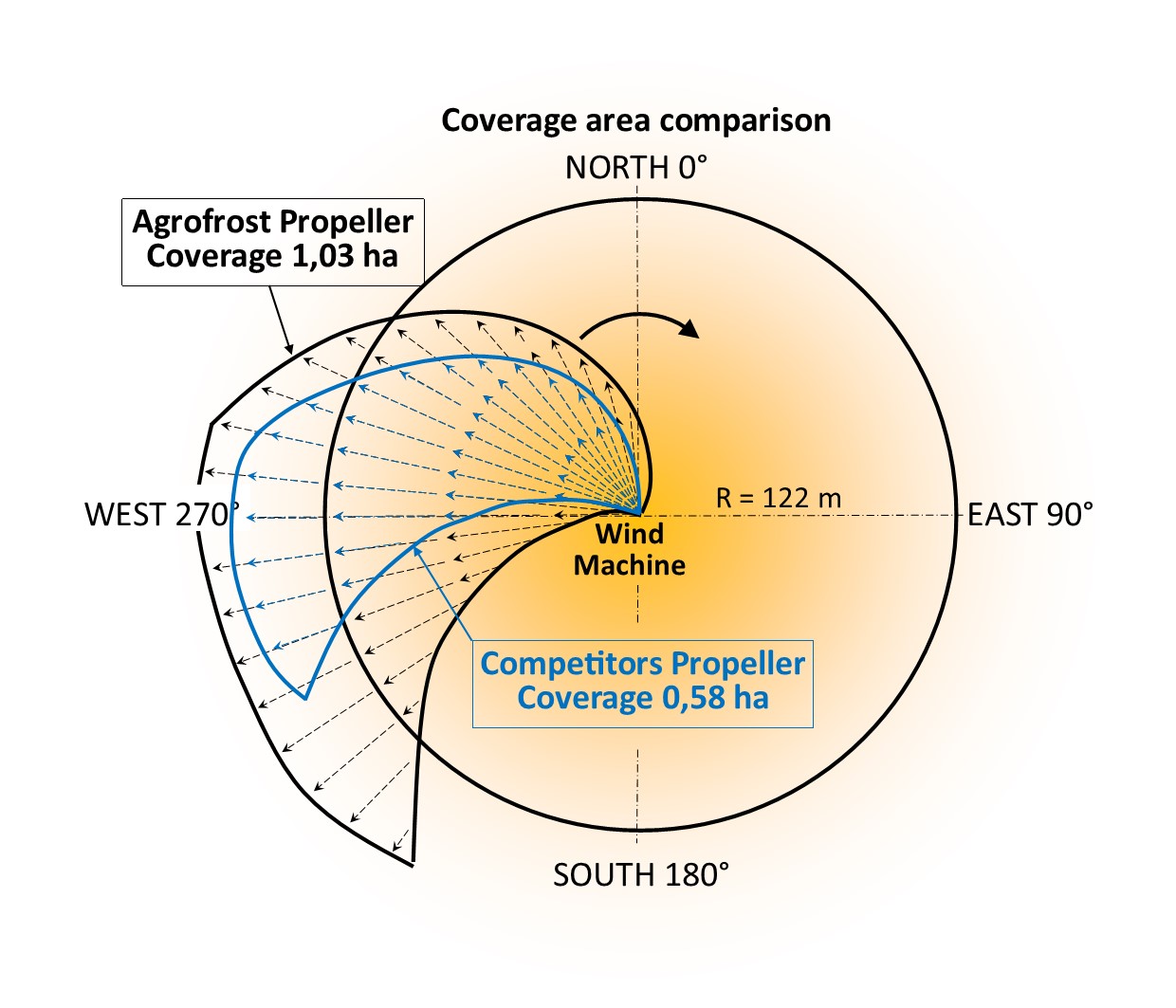

- Our propeller is the most powerful on the market and produces a lot more air. (see Fan Blades)

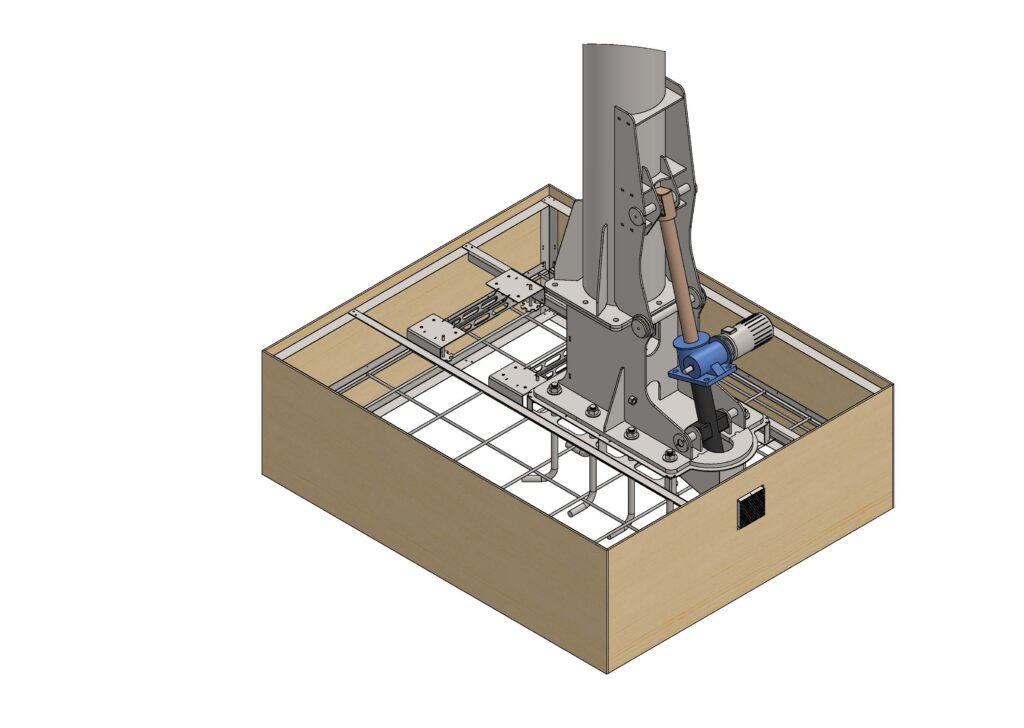

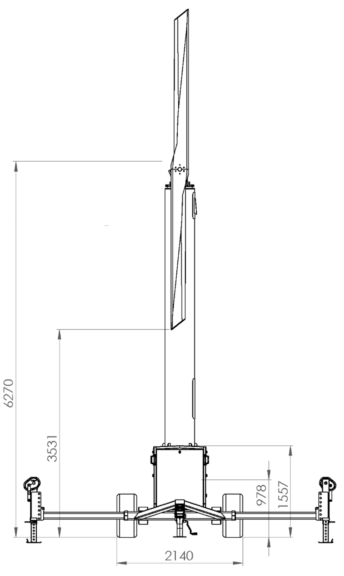

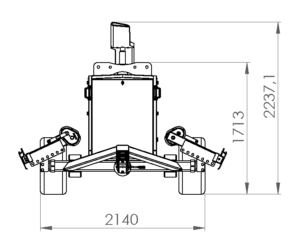

- Our tower can be set up and laid down by an electrical or hydraulic jack, which makes installation and maintenance a lot safer, easier, faster and cheaper. To put it up and down, the drivelines do not need to be disconnected (optional). (see Electrical Set Up)

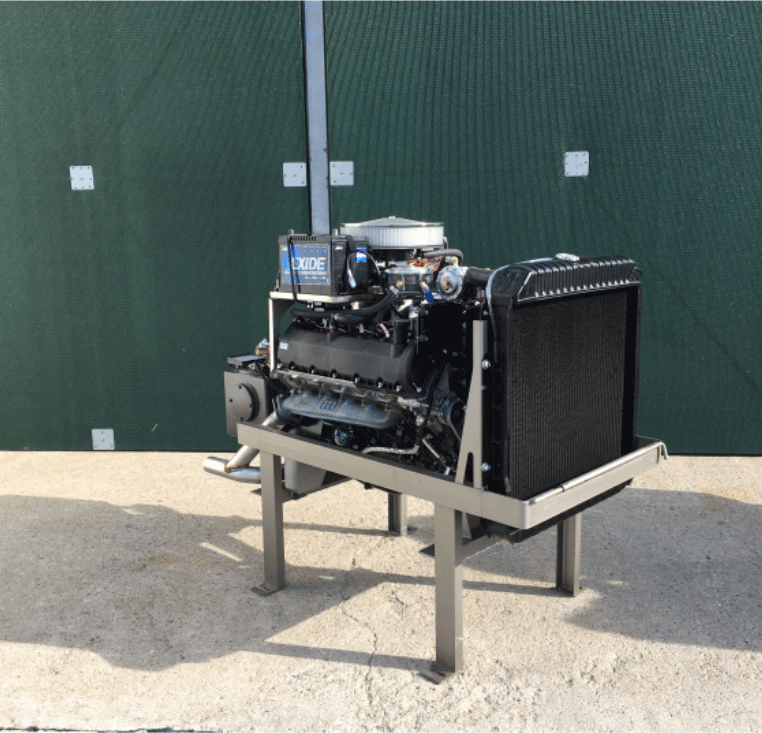

- Our engines are completely covered and insulated.

- Our gear boxes are pressure lubricated.